When do glass companies choose to automate the application of easy clean glass coatings?

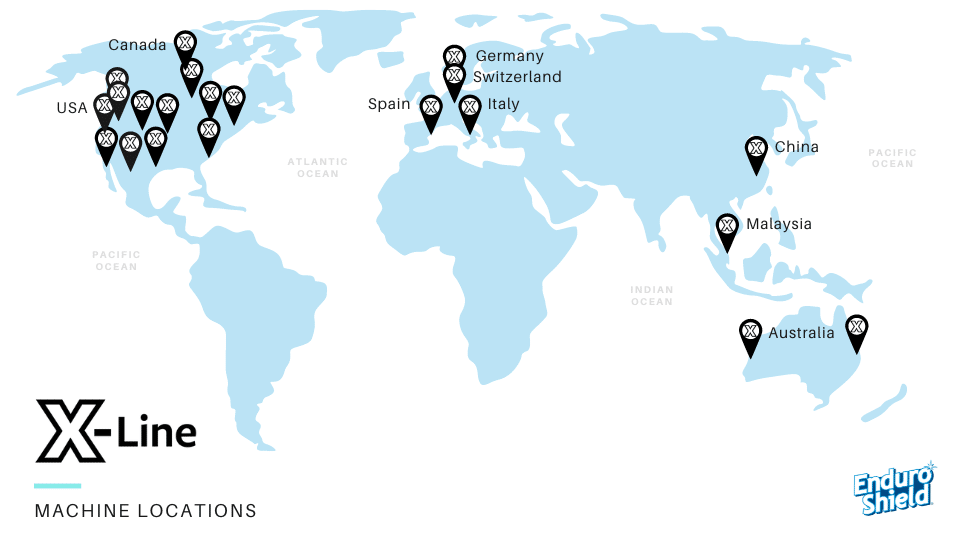

We are fortunate to partner with and supply easy clean glass coatings to customers of varying sizes all over the world. These glass companies operate in various industries such as shower glass, railings, pool fencing, windows and automotive. In turn, these companies have customers with different and often unique requirements.

Examples of these requirements can include the supply of large product ranges of different sizes, the need to efficiently provide high-volume glass products or the need to provide unique custom glass products that require fast turnaround.

It is from the experience that we have gained in working with these global partners that we have learnt the importance of developing solutions that fit the needs of these glass companies so they can better provide to their customers.

This is especially true when considering the application process of easy-clean glass coatings. When our partners feel the time is right to consider automation, we are often asked “What criteria should we consider when deciding the time is right to automate the application of an easy clean coating solution in our factory?”

Automating the application of coatings can have significant benefits over manual application and there are several factors that we discuss with our customers to help them arrive at the best solution for their needs.

These factors include:

- Volume & Speed: Automation of the coating process allows glass companies the ability to efficiently treat high volumes of glass at speed either in-line or at a dedicated location in the factory, reducing production time and handling.

- Labor & Productivity: A reduction in the reliance on manual labor combined with an increase in coverage efficiency compared with the cost of the machine over its life with the added potential to remove handling errors and the reduced requirement for staff training. As one of our automated partners said “robots turn up to work.”

- Different Glass Sizes: The ability to automatically treat different glass sizes when you require them without the need to batch. In 2023 / 2024 we have been approached by more glass fabricators than ever before – of all sizes – looking to automate their coating business. We also have X-Line machines in Europe that are exclusively for etched glass.

- Flexibility: The flexibility to automatically treat single side or double side through the same machine without any manual handling to meet your production needs.

- Metric Tracking: Automation machinery includes software with built-in metrics to track the volume and coverage rates of treated glass giving you better visibility of your production.

- Location including horizontal or vertical machinery: Choosing the best location in the factory to automate the coating so as not to interrupt production flow is a key consideration. The most common locations are straight after a tempering line or just before the final inspection and packaging. Every floor plan is different which is why there are options for single or double-sided vertical and horizontal machinery models.

To help guide our partners through the decision-making process, the team at EnduroShield have developed online machinery configurators that glass companies can utilise to determine the best automated solution for their needs. There is also a comprehensive tool for calculating profit, machinery payback time and machine capacity based on a number of inputs including volume of glass, labor costs, selling price, annual maintenance and energy consumption.

Try our Online Machinery Configurator & Discover the right automated solution for your business

This configurator produces a customized machine with specifications and pricing based on your unique inputs including loading and unloading options that can be downloaded and shared with your team.

Automate what you want, when you want

EnduroShield is the industry benchmark and leading manufacturer of protective, easy-clean coatings and coating machinery. Ease of application, durability, and proven field performance enables EnduroShield to stand out from the competition.

Many of the world’s leading glass fabricators choose EnduroShield and X-Line to produce easy clean, low maintenance glass that offers great value to customers; an innovative product and value-added solution that can be easily integrated into existing manufacturing lines.

Please contact us to see how you can be successful with EnduroShield and explore its potential to protect glass surfaces.

WORK WITH US

Want to collaborate with EnduroShield? For more information, reach out to our team.