The Benefits of Protective Glass Coatings

Tips for the glazing contractor and the end-user.

by Brad Thurman | Vice President at General Glass International

We are living in a different world. The pandemic shaped the way people view and approach everything, and the design and construction industry is no exception. In addition, sustainable building design continues to be top of mind. Designers and architects are tasked to adapt to a new normal with products that directly speak to the client’s concerns while remaining stunning in both aesthetic and performance.

Glass has always been an ideal building solution owing to its broad applications, functionality, as well as the abundance of design options. Designing for durability, wellness, and ease of use places glass surface protection high on the list of value-add glass enhancements, satisfying the needs of a project both practically and visually.

Why Protect Glass Surfaces?

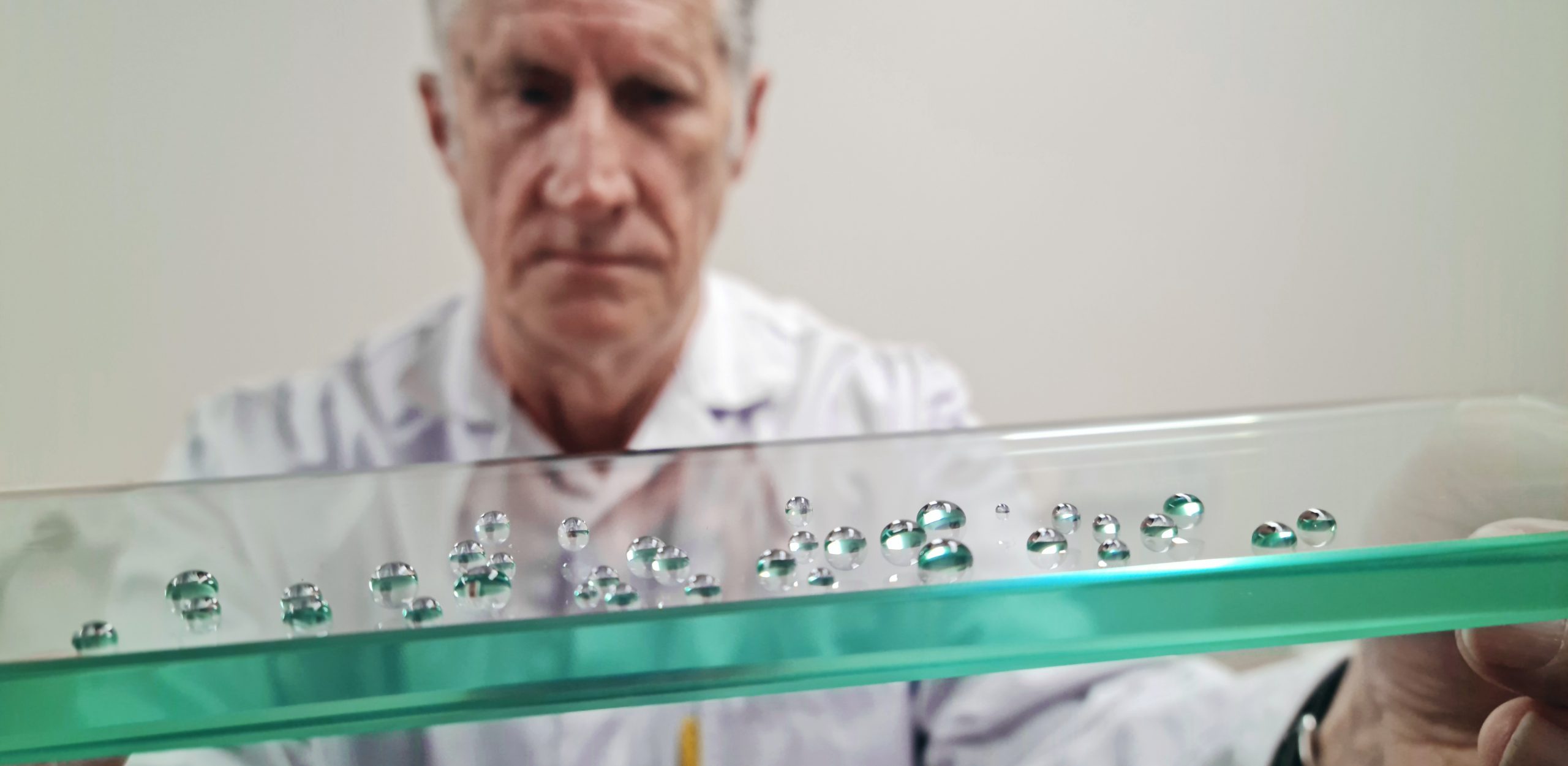

Glass surface protection is an application designed to protect glass from corrosion caused by excessive exposure to water, humidity, minerals, dirt and other contaminants, all while maintaining its clarity. Depending on the capabilities of the manufacturer, glass surface protection can be used across a wide variety of interior and exterior applications for both home and commercial construction projects. Clients will enjoy its longevity, minimal maintenance, and durability. There are various types of glass surface protection available today.

1. Permanent Coatings

Shower glass protection coatings, similar to pyrolytic low-emissivity coatings, are permanently fused into the glass at the manufacturing level and come with a limited lifetime warranty. The coating permanently protects the glass against the typical contaminants that oxidize and dull the appearance.

These products come from the float glass manufacturer, with only one side of the glass treated with the coating. The coating is highly durable, requires no reapplication, and it must be tempered. Permanently coated products, stored prior to tempering, typically have a shelf-life lower than applied alternatives. Some fabricators may also have issues tempering the glass, which may result in lower yields and a higher internal rate of rejection.

2. Factory-Applied Coatings

These coatings are applied post-tempering by certified glass fabricators that use specialized machinery for a high-quality, uniform finish. They can be applied to one or both surfaces of most any glass type or configuration. As the coating is factory-applied, the finished products arrive complete and ready to be installed.

Factory-applied coatings offer a range of benefits for both the contractor and the end user, including protection against sun damage and staining and the elimination of the need for harsh and often toxic cleaners. This, in turn, reduces the need to replace the glass down the line. Designed for both permanent and semi-permanent results, factory-applied coatings typically provide a 10-year limited warranty. Some coatings, such as GGI’s Enhance glass surface protection (powered by EnduroShield), offer a limited lifetime warranty for interior applications—with a 10-year warranty for exterior use.

3. Hand-Applied Solutions

Aftermarket solutions are hand-applied by the glass fabricator, glass installer, or the end user, and are available at stores like Lowes and Home Depot. These solutions can be applied to one or both sides of the glass.

The upfront cost is less than other options, but does not include labor, which can be intensive for whoever applies the solution. Additionally, time may prove this option to be the least cost-effective, as the need for periodic reapplication is common.

Because it is hand applied, the coating runs the risk of not being uniform. In the end, these provide less value to the contractor than the customer, as the customer may opt to apply the coating on their own.

For performance and value, factory-applied coatings provide the largest return on investment, saving time, reducing the need for replacements or retouches, all while satisfying the durability and wellness concerns prevalent among today’s consumers. The case for glass remains strong no matter which option is chosen, for its range of functions, applications, and customizations.

Misconceptions & Design Considerations

Products treated with glass surface protective coatings are not self-cleaning. These solutions do, however, make cleaning easier and they keep the glass looking cleaner and clearer, longer. The oleophobic and hydrophobic nature of glass surface protection solutions help create cleaner, healthier environments, but should not be confused with antimicrobial glass.

It is important to evaluate the characteristics of the product, how it is applied, and how the warranty process works, before you purchase as these vary among suppliers.

Recent Posts

When do glass companies choose to automate the application of easy clean glass coatings?

When do glass companies choose to automate the application of easy clean glass coatings?We are fortunate to partner with and supply easy clean glass coatings to customers of varying sizes all over the world. These glass companies operate in various industries such as...

Vitrum Glass Group with EnduroShield: Glass Fabrication & Coatings At Their Finest

Vitrum Glass Group with EnduroShield: Glass Fabrication & Coatings At Their Finest With a legacy of excellence in glass fabrication and manufacturing, Vitrum Glass Group remains dedicated to delivering top-notch architectural products and exceptional service. For...

Worried about white grout? Try this…

The easy-care finishing touch you need for kitchens, bathrooms and laundries.White on white tiles and grout have been used in wet areas for what seems like forever. There is no denying the popularity of this classic combination and it doesn’t look...

How to create an easy to clean family bathroom

Enduring Beauty - Create a cohesive, timeless and easy-to-clean family bathroom Heather and Sarah, the design duo behind Oak & Orange, pride themselves on designing dream homes for the modern family that are both practical and beautiful. Here...

GET THE LATEST – FOLLOW OUR STORIES ON INSTAGRAM

Follow us on Instagram to keep up to date with our latest projects, how-to guides, and product reviews.

Error: No feed found.

Please go to the Instagram Feed settings page to create a feed.

Contact Us